1984 Porsche 928 S Bumper Grill Restoration

This 1984 Porsche 928 S has been in the shop for some repairs, service, and minor restorations. It was a gray market car, imported to the USA and originally sold in Germany. Some modifications had been performed at different shops previously that was not to our customer’s liking. One of the items we repaired in house was rebuilding the transmission and repairing the broken gauge cluster. Another item was trying to find a new old stock OEM exhaust to replace the awful sounding aftermarket exhaust – which to our amazement, we did. Another item on our customer’s wish list was to source a original lower center, 928 S bumper grill.

Sourcing the Grill

We were able to source a complete unit, in decent shape, which was not inexpensive even in this poor condition. We looked over the product listing photos and knew a thorough restoration was going to be necessary. This was definitely something we knew we could tackle in house. These photos below show the condition when the grill arrived.

When we received the grill we noticed all the hardware was rusty, so that would need to be refurbished or replaced. Also, the plastic brackets that hold the aluminum grill inserts were painted. They were also on the brink of breaking and extremely flexible. Those would also need to be replaced. Even though the brackets are still somewhat available on some specialty websites, we had an idea on how to upgrade these while still retaining the OEM look. Since we have multiple 3d printers in house, this technology was first thing that came to mind.

Disassembly

First, we started by disassembling everything and bagging and inventorying all the hardware. We took the metal grill inserts to our in house powder coating department to get stripped, blasted and coated.

Drafting the CAD Files

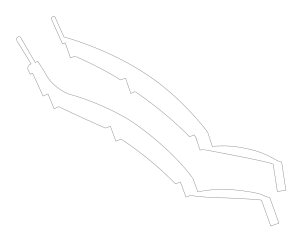

While the grill inserts were in powder, we took the brackets and scanned the profile them on a flatbed scanner. Since flatbed scanners, scan to a 1:1 ratio, we knew the profile sizing and dimensions on screen would be 100% perfect. We took the scans into Adobe photoshop and manipulated the contrast to make it easier to see the profile. After that, we saved the file and imported it into Adobe Illustrator. This is where we created vector outlines of the center and outside brackets. After the profiles were established, we deleted the imported scanned image and exported the file to a CAD format. We imported that into Fusion 360, where we drew up our 3d model for printing.

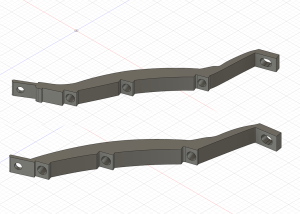

While in Fusion 360, we added additional supports, removed all the recesses that the OEM bracket have and pocketed each of the 5mm screw holes. Below is the transition of the files, from start to finish.

- Flatbed Scans 1:1 Ratio

- 2d Vector Profiles Drafted

- Final CAD Drawings Rendered

- CAD Drawings Top

After the Fusion 360 CAD drawings were complete, we exported these to a .STL file and sent them to the 3d Printer. Our AnyCubic Kobra Max is capable of printing 15.9″ x 15.9″ x 17.7″ Tall. We can print a wide variety of materials such as PLA, TPU, and for more industrial applications, carbon fiber nylon blend.

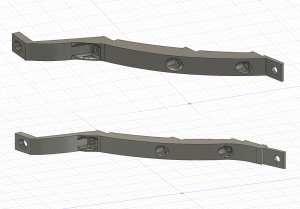

Once the parts came off the printer, we mocked up the grill inserts to the brackets. To our amazement, the brackets fit really well, directly off the printer. Immediately we noticed how much stronger these were compared to the OEM brackets. Furthermore, the reinforcements allowed for very little flex to the upper grill section. We performed some minor finish work and deburred the pieces. When the grill sections came out of powder coating, they would be ready to assemble.

Assembly

At this point in the project, the grill inserts were out of powder coating and ready to go with a fresh coat of Cardinal Powder Semi-Gloss Black T002-BK08. We now started assembling the grill. However, one thing that was not compensated for while designing the brackets was the thicker tolerances. When we reinforced the brackets joints in programming, we made them thicker than the OEM measurements. Our hardware was a little too short. We sourced some metric black oxide socket head screws that were 3mm longer.

- Polycarbonate Carbon Fiber Grill Supports – Porsche 928

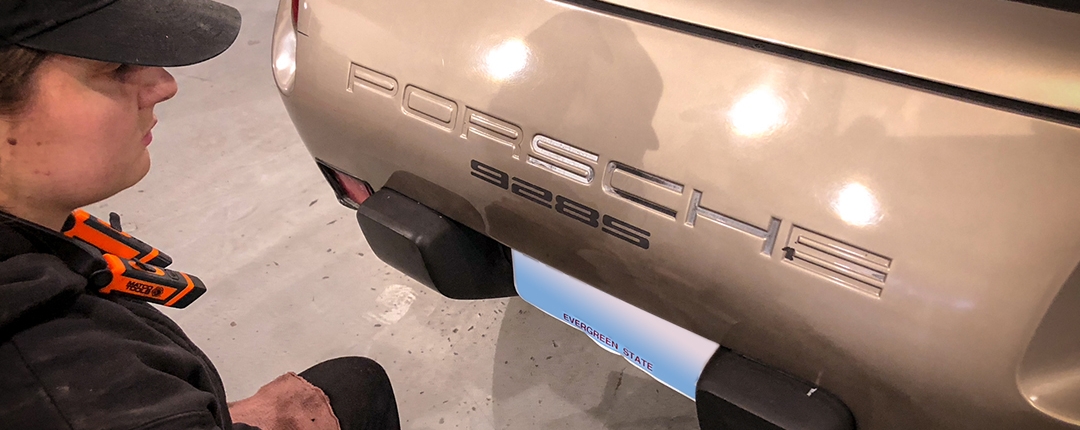

While installing the bumper grill, we found out a interesting thing. The North America (NA) bumpers grill brackets are different than the European E-Code bumpers. The brackets have a slightly different mounting location due to the fact that they are slightly shorter. To sold this, we had to modify the lower mount to be able to accept the NA brackets. It wasn’t worth printing new parts as we just had to drill a hole in each lower bracket and trim off the bottom tab just a little.

This is how it looked after installing the grill:

- Porsche 928 Grill Supports

- Porsche 928 Functional Application

In conclusion, the assembly went perfect after sourcing those. Overall the project turned out really nice. We believe our customer will be really happy with the final outcome. Stay tuned for our next post where we remove and install the rear Porsche 928S decals and repair the gauge cluster using 3d printing technology again.

For more information on how to get your Porsche back to OEM condition, please call 425-254-0627. You can also email us by clicking here. Meister Werks European & Import is located one block south from The Renton Landing in Renton, WA, across the street from the former Boeing Store and on the westside of the Paccar / Kenworth plant.