Headlight Refurbishing • Mercedes E320 CDI – W211

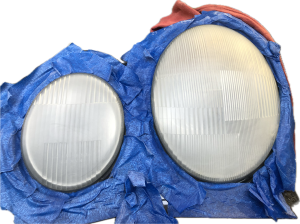

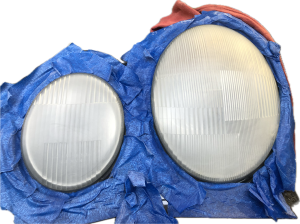

Last week we performed a headlight refurbishing on this Mercedes E320 CDI W211. The headlights were in very poor shape, heavily oxidized, yellowed and the light distribution was almost not existent. We are able to bring our customer’s headlights back to almost brand new using our proprietary methods. This will make them look like brand new and will not fade or oxidize for another 20-30 years.

The reason headlights fade is the plastic or acrylic breaks down over time. The hardeners in the plastic will evaporate with heat and UV. This happens in hotter and sunnier climates faster than it does up here in the Seattle area. Road debris will also cause the headlights to become pitted and foggy. The only way to repair this is to replace the headlight housing itself. We can so replace the lens (if possible) or do a headlight refurbishing to the vehicle. Unfortunately this Mercedes E320 does not have the capability of replacing the lenses and housings were just too expensive for our customer.

To replace these headlight is a in depth job. The labor time to remove the bumpers and replace the lights is over double than just refinishing both headlight lenses. During this process we mask the entire front of the vehicle and cover the back half, insuring that there is no over spray on the vehicle.

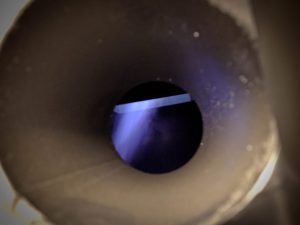

Next we prep the lenses to ensure a good and permanent adhesion. We remove as many low spots on the lens that we can and any impurities prior to the headlight refurbishing.

Lastly, we spray the headlights with a two part liquid acrylic that bonds directly to the acrylic headlight lenses down to molecular structure. Having the same material on the lens allows the molecular structure to bond better than any other protective coating or buffing kit on the market. This means that it will never come off, fade or discolor for another 20-30 years. It’s also UV fast, so it will take a long time for UV to break down the lens.

Headlight Refurbishing 6.25.19:

The headlight refurbishing service we provide is meant to restore the lens output quality back to 99%. It is impossible to make them 100% perfect as we can not remove the lenses and remove blemishes that are behind the lens. We also may not be able to remove all pits in the lens as sanding them down too much can cause the light output to distort. If you want 100% [perfect lenses, we suggest purchasing new headlight housings, in which Meister Werks also sells and provides as a installation service.

Headlight Refurbishing 12.28.24:

Last week one of our customer brought in their 2002 E320 for the same headlight refurbishing treatment. Additionally we can perform this service on any European vehicle with faded plastic lenses. For example, Porsche, BMW, Audi, , VW / Volkswagen, & Mini. With our new equipment, we can perform this service within one day. Drop your car off at our 8am drop off time and we’ll have it complete by 5pm or before. Our new equipment and products have faster cure times. Like before, it also maintains the same quality and durability of a brand new headlight lens. While your vehilce is with us, we will also perform our signature courtesy 30 point inspection just to make sure everything on your car is safe.

-

-

Before

-

-

After

To make an appointment for your headlight refurbishing contact us at 425-254-0627 or email us. Meister Werks European & Import is located one block south from The Renton Landing in Renton, WA in the Seattle, WA area.