Mounting and Balancing Tires on Flat Lip 3 Piece Wheels

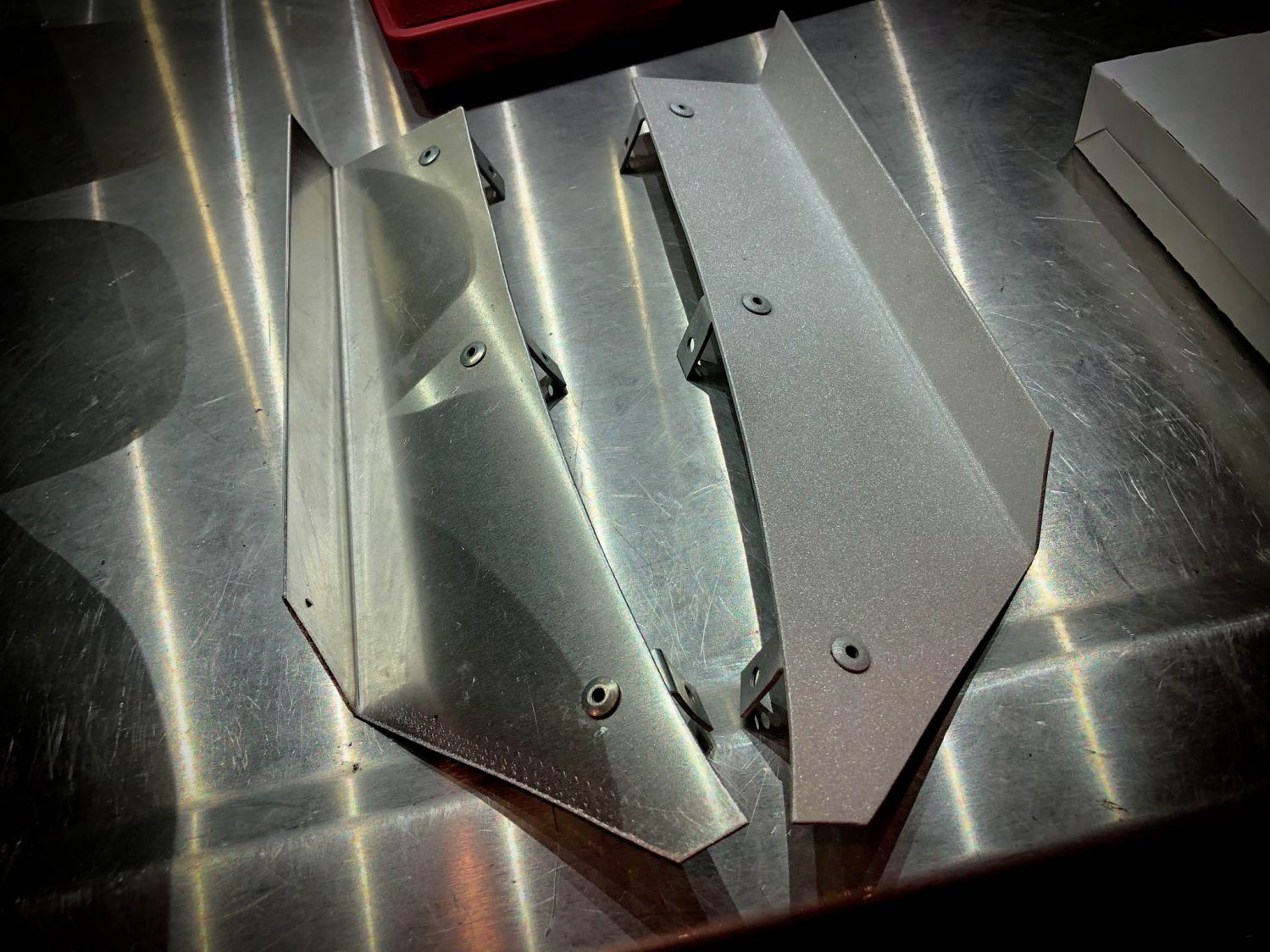

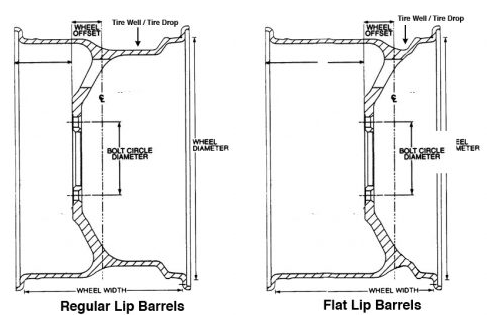

We regularly receive jobs in the shop for mounting and balancing tires for flat lip, 3 piece wheels. This can pose a challenge as the back barrels do not have a drop for us to dismount the tire properly.

We regularly receive jobs in the shop for mounting and balancing tires for flat lip, 3 piece wheels. This can pose a challenge as the back barrels do not have a drop for us to dismount the tire properly.

When performing this service, we have to remove the face side tire first. We always use the Motion Pro Rim Shield guards to protect the wheel lips. After that, we remove the tire from the machine. Using the bead breaker, we push the rest of the tire off into the tire well or tire drop portion of the wheel. Once this is achieved, we return the wheel and tire to the machine and remove the rest of the tire. Mounting can also be challenging, but in this video instance, there was not a problem. People with stretched tires will have more issues getting them to bead on the wheel lip beads correctly.

Even though this video is sped up, this requires more labor to remove the tire. We charge an hourly rate for all custom 3 piece wheels. If you have a standard wheel, made by your vehicle’s manufacturer, there is no need to worry. There will not be any additional charge for standard wheels.

With a purchase of tires at Meister Werks, we also offer free flat repair, free tire rotation and we will warranty your tires if there is a warranty issue with the manufacturers milage warranty. Anther service we offer is wheel alignment. On our state of the art 3d laser alignment machine, we will be able to dial in your alignment. This will eliminate unnecessary tire wear and prolong the life of your tires.

To make an appointment to have your tires changed, call 425-254-0627 or email us. Meister Werks European & Import is located one block south from The Renton Landing in Renton, WA.