Meister Werks happy to announce that we will be offering a 10% discount to all PNW Miniacs car club members. This discount is good up to $100 off any service, maintenance, repair or performance item. Contact the PNW Miniac Car Club for further details.

Meister Werks happy to announce that we will be offering a 10% discount to all Mini Addicted car club members. This discount is good up to $100 off any service, maintenance, repair or performance item. Contact the Mini Addicted car club for further details.

About Mini Addicted

The Club name speaks for it’s self “MINI ADDICTED”. This social club is all about the MINI. We love the idea that no two MINIS are alike. We enjoy customizing, modifying and adding our own character or twist to the MINI. This social club is here for sharing experiences, car knowledge, photos and building new friendships.

This club will have meet ups, events, drives, photo shoots and attend car shows. We are a Pacific Northwest club only, so you must live in Washington, Oregon or Idaho plus you must own a Mini to be a member. There are no dues involved in this club but there are logo/stickers and club shirts and hoodies available to order. This social club is here for all members to feel welcomed, accepted and feel they are apart of the MINI Community. The MINI ADDICTED car club was founded by Lori Aaron Sept 2017 as a private page, it then went to a closed group in 2018.

Project 1991 Mercedes-Benz 560sec

It’s been a long road to completion but we finally got Project 1991 Mercedes-Benz 560sec finished today. Our customer came in about 6 months ago wanting to do a air suspension install on his 1991 Mercedes-Benz 560sec. We wrote him a quote based off his needs and some suggestions from Meister Werks. After approving the quote we ordered all the parts necessary to install his custom setup. The customer also wanted us to have the bumpers, side mouldings, mirrors and door handles painted white to match the body. We contacted our friends at Automotive Solutions to come out and do all the body work, prep and paint.

Fast forward a few weeks later, Covid-19 / Coronavirus hit the Seattle area and thus started the parts delays. It took a few months of waiting to get all the parts in. A few months later in March, we finally received everything and the install started very soon after. We also installed a kit on this customer’s 1990 Mercedes-Benz 500SL, which can be seen by clicking here.

The Install Begins

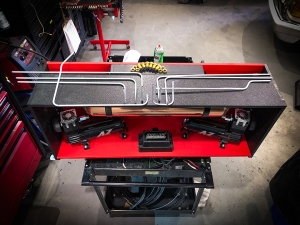

We began the install by removing the bumpers, side mouldings, mirrors and door handles. While these parts were out, we started polishing the OEM stainless steel trim. After all the parts went into paint, we began the air suspension portion. We started the air system by disassembling the custom stereo setup in the trunk. The car stereo installer had fabricated a custom enclosure to house the rose gold plated air tank, Air Zenith air compressors and Airlift 3p manifold. We bent custom hard lines, powder coated them white (to match the body) and affixed all the fittings to the components.

After we did this, we installed them into the custom build enclosure. Additionally, we wired the Air Zenith OB2 compressors with 4 gauge wires and 80 amp fuses. Futhermore, we ran the custom harness to the Airlift 3p manifold, then connected the remote wire to the ignition circuit. Once that was complete, we installed the 3p controller in the Mercedes-Benz 560sec center console.

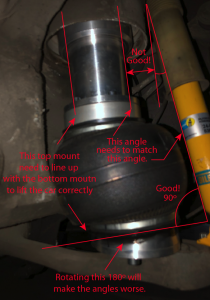

Air Suspension Issues

We had many issues with the custom air bags we purchased from a company in Germany. The bags were rubbing on the body and the upper bag mount did not line up with the control arms. Countless hours corresponding, assembly, disassembly, reassembly, photos and diagrams were sent to the manufacturers. After weeks of communications, we finally got results and newly machined parts were shipped from Germany. After 3 additional weeks, we received new parts. Unfortunately the parts still did not work right. So we decided to machine the new parts in house to get them to work. What we machined was perfection and will be able to replicate this on any future projects. This Mercedes-Benz is now able to air up properly, lay frame and not rub on the body. These additional modifications to the air suspension were much better than the original kit.

More Custom

We also had to delete the Mercedes-Benz factory hydraulic suspension. To do this we removed the rear shocks, removed the hydraulic pump on the engine and machined a custom block off plate. We used 6061 T6 aluminum to machine this part in our inhouse machine shop. We also made a custom gasket on our CNC laser cutter. Everything installed perfect, with no leaks or issues.

Wrapping it up

With the components installed, we attached the air lines using OEM brake line clips to secure the air lines in place. While all this work was being done, we assembled and sealed the wheel. These were custom plasted rose gold on the AMG monoblock wheels. After sealing these three piece wheels, we mounted and balanced the tires. After test fitting the wheels, we knew we needed spacers on the front. To give this beautiful Mercedes-Benz 560sec a flush fit, we installed 20mm spacers all the way around.

After all of this hard work, we finally were able to test the system. We checked for air leaks, buttoned up the trunk, and make sure all the small details were ironed out.

Project 1991 Mercedes-Benz 560sec Build List

- Airlift Performance 3p management

- OB2 dual air compressors

- 4 Gallon Specialty Suspension seamless air tank – plated rose gold*

- Custom hard lines at Meister Werks

- Air suspension install at Meister Werks

- Front bags & hydraulic pump block off plate custom machined at Meister Werks

- Rose gold plated* AMG wheels & OZ lips & barrels assembled and sealed at Meister Werks

- Bumpers, mirrors, door handles, moldings, body work & paint at Meister Werks by Automotive Solutions

* All custom rose gold plating done at the customer’s shop in California.

To make an appointment for your custom air ride, stop by or call 425-254-0627. You can also email us by clicking here. Meister Werks European & Import is located one block south from The Renton Landing in Renton, WA, across the street from The Boeing Store and on the westside of the Paccar / Kenworth plant.

This week is vintage car week at Meister Werks. We’ve had a number of vintage vehicles come in such as a ’64 Coupe Deville, ’64 – 13 Window VW Bus, ’71 Beetle and a 1977 Datsun 280z.

Coupe Deville is in for a air compressor refresh and wiring. 13 Window Bus came in for a plethora of service, repairs and upgrades. The Clementine Orange Beetle was dropped off for a crate engine install, all new upholstery, disk brake conversions, powder coating and many more custom items. Lastly, the ’77 280z came in for some repairs and some custom powder coating.

The Z and the Coupe Deville will be done next week, although the VW’s will be ongoing projects over the next month. Stay tuned for further progress reports on each vehicle.

Meister Werks European & Import NAMED CARFAX TOP-RATED Service Shop

Verified Customer Ratings Used to Name the Inaugural CARFAX Top-Rated Service Shops of 2019

Meister Werks European & Import is being celebrated as a CAR FAX Top-Rated Service Shop based on verified reviews from actual customers. The exclusive list of service shops recognize in the inaugural CAR FAX Top-Rated Service Shops. These shops receive an average of 4.77 stars out of five on CARFAX Car Care.

“Our goal is help car owners make confident decisions,” said Mike Liou, head of Service Marketing at CAR FAX. “We have over 10 million active Car Care subscribers. These subscribers use the program to help keep up with maintenance and recalls on their vehicles. We want to utilize this community to highlight the service shops who are going above and beyond when it comes to customer care, and we do so with reviews from only verified customers.”

“Meister Werks is honored to be a Car Fax Top-Rated Service Shop”, said owner Dave Meister. “Our main objective is to provide our customers with the highest level of customer service. We also offer the best quality parts for repairs, service and performance on our customer’s European and import vehicles.

In February, CARFAX also launched the first-ever Top-Rated Dealer award to car dealerships. These are based on more than a million verified reviews.

About CARFAX

CARFAX.com, part of IHS Markit, helps millions of people every day. We help consumers confidently shop, buy, service and sell used cars, Coupled with innovative solutions powered by CARFAX. The expert in vehicle history since 1984, they provides exclusive services like Used Car Listings, Car Care, History-Based Value and the flagship Vehicle History Report to consumers and the automotive industry. Based in London, IHS Markit is a world leader in critical information, analytics and solutions.

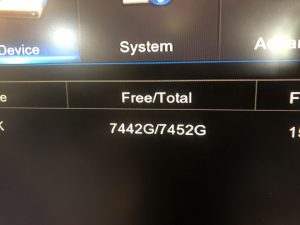

DIY Cobra 8 Channel Surveillance System – Upgrade to a 8tb Hard Drive

• Purchase a Sata hard drive for your Cobra 8 Channel Surveillance System. We got an 8gb external from Amazon for $140 w/ free Prime delivery

• Purchase a Sata hard drive for your Cobra 8 Channel Surveillance System. We got an 8gb external from Amazon for $140 w/ free Prime delivery

• After receiving the HD, format to MS Dos Fat 32. (You may not have to if it is already formatted for this. Most external HD are)

• Remove new hard drive from case.

• Power down Cobra 8 Channel Surveillance System and unplug power cord after the prompt on the screen says to do so.

• Remove old hard drive from Cobra 8 Channel Surveillance System.

• Install new hard drive into Cobra 8 Channel Surveillance System.

• Plug in power cord.

• Screen will prompt “HD Not Formatted”.

• Screen will prompt “HD Not Formatted”.

• Open the Settings Menu > Device. Select the new hard drive.• Click the format button.

• Now you have storage for 8 months of recordings with 4 cameras or 4 months with 8 cameras.

Powder Coated Brembo Calipers

Last week, we Powder Coated Brembo Calipers for a customer. The customer purchased brand new calipers for his 2015 Lexus GS350. Since these were brand new in the box, there was little prep we had to do. We outgassed the machining oils by baking the calipers for a short time in our powder coating oven. After the calipers cooled off, we prepped them with solvent, masked off the critical areas and plugged all the threaded holes. To mask and plug the holes, we use a high temp silicone tape and plug that will withstand the temperature of our oven. The makes for an easy and trouble free installation for our customers.

Last week, we Powder Coated Brembo Calipers for a customer. The customer purchased brand new calipers for his 2015 Lexus GS350. Since these were brand new in the box, there was little prep we had to do. We outgassed the machining oils by baking the calipers for a short time in our powder coating oven. After the calipers cooled off, we prepped them with solvent, masked off the critical areas and plugged all the threaded holes. To mask and plug the holes, we use a high temp silicone tape and plug that will withstand the temperature of our oven. The makes for an easy and trouble free installation for our customers.

After the prep is done, we powder coat the calipers, 2 coats of super durable wet red and 2 coats of clear coat. This will ensure the maximum amount of protection against road debris, discoloration and durability. As you can see, the finish turned out flawlessly.

Questions We Have Asked

Many people ask, “Why don’t you seperate the calipers (if they are 2 piece) or remove the pistons? The answer is many reasons:

Many people ask, “Why don’t you seperate the calipers (if they are 2 piece) or remove the pistons? The answer is many reasons:

- First, you don’t want to separate the calipers. We’ve encountered customers who tried this and they will never seal again. This is because the caliper may slightly become disfigured from relieving stress and the torque to reassemble them. Also, the heat when baking does not help in this scenario.

Second, the pistons will heat up at the same rate of the caliper housing. This will protect against any media or powder getting into the brake cylinders. On used calipers, we have to media blast the brake dust off the calipers. We do not want to get meida inside the cylinder, which could affect braking performance.

Second, the pistons will heat up at the same rate of the caliper housing. This will protect against any media or powder getting into the brake cylinders. On used calipers, we have to media blast the brake dust off the calipers. We do not want to get meida inside the cylinder, which could affect braking performance.- Third, the dust seals. This will not affected by temperature change. Furthermore, the seals stay perfectly sealed and are make to take the temperature of high performance braking temperatures.

- Lastly, Powder Coated Brembo Calipers is much easier for us as there is less to mask and prep.

Used Calipers

We can coat used brake calipers, however the process requires more prep. We have to heavily outgas the caliper to get all the brake fluid out of the caliper. The powder coat will be destroyed if any brake fluid gets on it during the curing process. We also have to remove `100% of the old brake dust. Brake dust is non conductive and the powder will not stick to it. If the calipers are on the vehicle, we charge more to remove, prep, coat and reinstall them. They also need bleed so essentially, if they are already on the car, it’s sometimes better to paint them. You can see this process by clicking here.

For more information on how to get your brake calipers painted or powdercoated, please call 425-254-0627. You can also email us by clicking here. Meister Werks European & Import is located one block south from The Renton Landing in Renton, WA, across the street from The Boeing Store and on the westside of the Paccar / Kenworth plant.

TTRS Performance Upgrades

The inline 5 may be the most stout engine ever produced by Audi.  But for some, the best is simply not enough… A long time customer brought in his 2018 Audi TTRS for a Carbon Cold Air Intake, 4 inch Turbo Inlet, Wastegate Lines and to top it off with a Stage 1 tune all supplied by Unitronic.

But for some, the best is simply not enough… A long time customer brought in his 2018 Audi TTRS for a Carbon Cold Air Intake, 4 inch Turbo Inlet, Wastegate Lines and to top it off with a Stage 1 tune all supplied by Unitronic.

UNITRONIC STAGE 1 FOR AUDI TTRS MK3 2.5TFSI EVO

• STOCK POWER: 400HP / 354LB-FT

• After Tune: 476HP / 469LB-FT

Unitronic Stage 1 Performance Software is for vehicles with 91 octane / 95 RON fuel, on a completely stock car. It is the performance upgrade that will result in the most gains! Performance Software for your ECU Box Code is subject to availability. 2019+ models may require to have the hood opened during the flashing process.

UNITRONIC STAGE 2 DSG FOR AUDI TTRS MK3 2.5TFSI EVO

Flashed directly through the (OBDII) Diagnostic port of your vehicle (10-15 minutes). Unitronic’s TCU Performance Software calibration enhances the gear shift speeds making them up to 70% quicker. D-mode (Drive) is for everyday daily driving and economy, while S-mode (Sport) is for faster acceleration. Unitronic’s TCU Performance Software unlocks the factory launch control limiter. The OEM launch control limiter blocks the engagement of launch control after only 200 launches.

Unitronic’s Stage 2 TCU Performance Software calibrations increase TCU torque limiters to allow for an increased output. It’s been developed alongside Unitronic’s upcoming Stage 2 ECU Performance Software for the ultimate overall experience. Unitronic’s Stage 2 TCU Performance Software calibrations increase clutch clamping pressure. It is perfect, alongside Unitronic’s Stage 2 ECU Performance Software. This supports an increase in engine torque output and ensuring that the clutches properly grip . This also will help for the higher output to be sustained. Includes all Stage 2 tune variants and all lower software stages as well.

For more info on these products, check out the Unitronic Website by clicking here.

To make an appointment for your TTRS, Audi or European car, please call 425-254-0627. You can also email us by clicking here. Meister Werks European & Import is located one block south from The Renton Landing in Renton, WA, across the street from The Boeing Store and on the westside of the Paccar / Kenworth plant.

Powder Coated Production Run of Reinforced Clutch Forks

Today we powder coated a production run of reinforced clutch forks for Flipside Customs. These VW clutch forks are for 02A & 02J transmission and reinforced with the factory clutch fork in house at Flipside Customs in Renton, WA. These new OEM forks receive a TIG welded finish with water cut gussets. Factory forks are know to bend and go bad. Symptoms include increasing difficulty getting into gear, especially 1st gear. Really fast clicking or chattering sound in neutral with clutch completely let out. Sound may completely disappear if you press in the clutch.

Today we powder coated a production run of reinforced clutch forks for Flipside Customs. These VW clutch forks are for 02A & 02J transmission and reinforced with the factory clutch fork in house at Flipside Customs in Renton, WA. These new OEM forks receive a TIG welded finish with water cut gussets. Factory forks are know to bend and go bad. Symptoms include increasing difficulty getting into gear, especially 1st gear. Really fast clicking or chattering sound in neutral with clutch completely let out. Sound may completely disappear if you press in the clutch.

If you are interested in getting powder coating quote for your production run of in house manufactured parts, contact us at 425-254-0627. You can also email us by clicking here. Meister Werks European & Import is located one block south from The Renton Landing in Renton, WA, across the street from The Boeing Store and on the westside of the Paccar / Kenworth plant.

About Flipside Customs

Flipside Customs owner, Rob Hancock, specializes in custom design, fabrication and welding services. Customers can expect an increase in functionality, performance and overall quality with his 20 years of experience. Rob started his career working on street rods; a passion passed down through the generations. While continuing to work on street rods, he branched out to production based welding on speed related products. He also gained experience in the machining industry which yet again expanded Flipside’s diversity. Rob has continued to use his skill set to benefit his customers in ways that separate his work from others.

Also, questions like; “Is this possible?” will be quickly answered with “let me show you how!”. As an avid racer himself, he saw and experienced several areas to improve on during his time on the track. He began designing, modifying and fabricating custom race components that have increased both performance and functionality both on and off the track. As a lover of both two and four-wheel vehicles, Rob has expanded the business to include custom motorcycles, street, and race cars as well as off-road vehicles. If you are interested in what Flipside Customs has to offer, please contact Rob at Rob@flipsidecustoms.com.